Introduction to Sludge Pumps

Sludge pumps are essential components in a wide range of industrial operations. Designed to handle thick, viscous fluids and semi-solids, these pumps are engineered to move sludge—an often abrasive and challenging material that can damage conventional pumping systems. Their robust construction and high-efficiency output make them indispensable in environments where reliability, performance, and durability are crucial.

In industrial settings, sludge pumps are often used for transferring waste, slurry, and other solid-liquid mixtures. Their application spans across sectors including wastewater treatment, mining, oil & gas, and chemical processing. Choosing the right industrial sludge pump can improve productivity, reduce maintenance, and lower operational costs.

This guide explores key sludge pump applications, the benefits of sludge pumps, and best practices to ensure optimal performance in demanding industrial environments.

Key Applications of Sludge Pumps Across Industries

Sludge Pump for Wastewater Treatment

Wastewater treatment facilities rely heavily on sludge pumps to handle sludge that results from the sedimentation of solid waste. These pumps are built to manage thick, high-solid-content sludge while ensuring consistent and reliable flow.

- Removes sludge from primary and secondary clarifiers.

- Transfers activated and digested sludge.

- Ensures compliance with environmental regulations by maintaining continuous processing.

Using a sludge pump for wastewater treatment enhances operational efficiency and plays a key role in reducing environmental impact.

Sludge Pump for Mining Operations

The mining industry deals with some of the harshest materials, including abrasive slurries, tailings, and chemical-laden sludge. A heavy-duty sludge pump is crucial for managing these materials safely and efficiently.

- Handles corrosive and abrasive mine waste.

- Reduces downtime and wear caused by thick slurry.

- Supports continuous operation in remote and rugged mining environments.

Sludge pumps for mining applications must be designed to withstand extreme operating conditions while delivering a high level of reliability.

Other Sludge Pump Applications in Industry

Besides wastewater and mining, sludge pumps are also used in various other sectors:

- Chemical Plants: For transporting sludge that contains aggressive chemicals and solvents.

- Food Processing: For handling food waste sludge with high viscosity and solid content.

- Oil & Gas Refineries: For dewatering operations and handling oily sludge.

Each industry presents unique challenges, and selecting the right industrial sludge pump depends on the specific requirements of the sludge material.

Benefits of Sludge Pumps in Industrial Settings

Integrating sludge pumps into industrial workflows offers a multitude of operational and financial benefits. Understanding these advantages is key to maximizing system performance and long-term ROI.

Efficient Material Handling

Sludge pumps are specifically engineered to manage viscous fluids and semi-solid materials that conventional pumps cannot handle efficiently. This includes:

- High-solids content

- Non-Newtonian fluids

- Abrasive or chemically aggressive materials

Their design allows for continuous flow and reduces the risk of clogs or blockages, which are common in traditional pumping systems.

Cost Reduction and Energy Savings

A properly selected and maintained sludge pump can lead to significant cost reductions:

- Reduced downtime and maintenance

- Lower energy consumption due to optimized hydraulic design

- Extended lifespan of components

In the long run, these savings can substantially outweigh the initial investment in a high-quality industrial sludge pump.

Reliability in Harsh Environments

Heavy-duty sludge pumps are built to perform under extreme industrial conditions. This includes high pressure, temperature fluctuations, and abrasive media. Their durability translates into:

- Fewer system failures

- Consistent throughput

- Improved workplace safety

Their ability to maintain performance under tough conditions ensures process continuity, which is critical for industries like mining and wastewater treatment.

Versatility with Various Sludge Types

Sludge is not a uniform material—it varies significantly across industries. Sludge pumps can handle a wide range of materials, including:

- Raw and thickened sludge

- Chemical-laden sludge

- Slurries with high particulate content

This adaptability makes them a go-to solution for multiple industrial applications.

Choosing the Right Heavy-Duty Sludge Pump

Selecting the ideal sludge pump involves assessing several technical and operational parameters. The wrong pump can lead to reduced efficiency, increased maintenance, and higher costs.

Factors to Consider

- Viscosity and Solids Content: Pumps must be able to handle high-viscosity materials and suspended solids without clogging.

- Flow Rate and Pressure: Ensure the pump matches system requirements for throughput and head pressure.

- Abrasiveness and Corrosiveness: Material selection (e.g., stainless steel, rubber-lined) is critical for longevity.

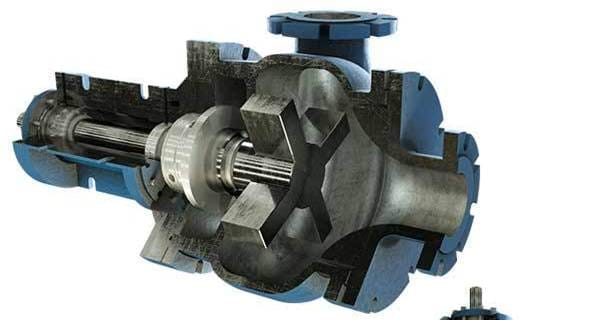

Material Selection and Pump Design

Industrial sludge pumps come in various configurations, such as:

- Centrifugal pumps: Good for low-viscosity sludges.

- Positive displacement pumps: Ideal for high-viscosity and high-solids sludges.

The design and material used in the pump should align with the nature of the sludge and the operational environment.

Comparison Chart: Types of Sludge Pumps

| Pump Type | Best For | Advantages |

| Centrifugal Pump | Low-viscosity sludge | High flow rates, simple design |

| Progressive Cavity Pump | High-viscosity sludge | Gentle pumping, minimal shear |

| Diaphragm Pump | Abrasive and corrosive sludge | Seal-less, low maintenance |

| Peristaltic Pump | Shear-sensitive sludge | No contact with pump internals |

Sludge Pump Best Practices for Long-Term Efficiency

Proper installation, routine maintenance, and operator training are critical for maximizing the performance and longevity of industrial sludge pumps.

Installation Best Practices

- Correct Alignment: Misalignment can cause premature wear and inefficiency.

- Stable Foundation: A secure base reduces vibration and prevents structural damage.

- Proper Piping Configuration: Avoid sharp bends or restrictions that may hinder flow.

A well-executed installation minimizes startup issues and ensures the system runs at optimal capacity.

Maintenance and Inspection Tips

Regular maintenance is vital for preventing downtime and ensuring long-term reliability. Key practices include:

- Daily Checks: Inspect seals, bearings, and flow output.

- Lubrication: Keep moving parts well-lubricated to reduce friction and wear.

- Wear Monitoring: Use sensors or manual inspections to monitor critical wear parts.

Adopting a preventive maintenance schedule instead of reactive servicing can significantly reduce repair costs and extend equipment lifespan.

Safety and Operational Guidelines

Industrial pumps operate under potentially hazardous conditions. To mitigate risk:

- Train Operators: Ensure staff understand pump operation, signs of wear, and emergency shutdown procedures.

- Use PPE: Require appropriate personal protective equipment during operation and maintenance.

- Lockout/Tagout Procedures: Always follow LOTO protocols during maintenance to avoid accidental startups.

Establishing strict safety and operational protocols helps prevent injuries and equipment damage.

Conclusion

Sludge pumps play a pivotal role in managing waste and material flow across various industrial applications. Whether used in wastewater treatment, mining, or other heavy industries, a well-chosen and properly maintained heavy-duty sludge pump delivers unmatched reliability, efficiency, and cost savings.

By understanding the benefits of sludge pumps, evaluating application-specific requirements, and following sludge pump best practices, businesses can ensure consistent system performance and maximize their operational ROI.